Winter is a time when we always get a spike in enquires about two age-old problems: condensation and insulation.

So, it’s a good time to consider retrofitting insulated roof sheets if you have an existing building – or to remember to include them on a new build.

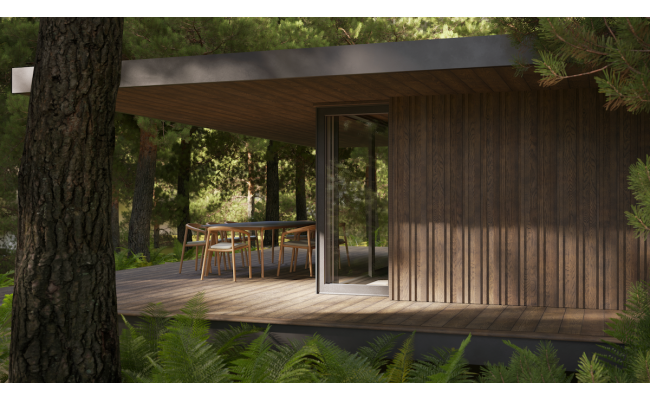

The rise in popularity of garden rooms and outbuildings in a domestic setting is making this issue more common.

Often these builds do not include roof insulation and it’s only when the weather turns cold that problems emerge.

Condensation occurs when it is warm inside a building but cold outside, creating condensation dripping on the inside.

The quantity of water in the air (humidity) is higher during the winter months and many garden rooms are almost air-tight, which increases the likelihood of condensation, too. Especially as people open windows less often when the outside air is cold.

Water begins to appear most often on the inside of windows. This is because glass is a good conductor and cools down in line with the temperature outside.

Condensation is also a major issue in garages, especially those which are stand-alone, away from the main building.

What are the biggest threats from condensation?

Dripping condensation can cause damage to the building and to its contents. But it can also be a threat to human health.

Aside from the issues of damp air it also leads to mould, which can lead to respiratory problems.

If you are working out in a home or garden gym room, you don’t want to be breathing in mould spores too often.

In fact, it’s often when mould appears that customers call us for a solution.

In addition, condensation has the potential to increase the decay of a building. It’s not a threat to bricks and mortar but it will impact internal decoration, for instance.

Impact in an industrial setting:

It is not only domestic buildings which are impacted. Condensation is also an issue in an industrial setting, for instance warehouses and factories- although thicker sheets are required to provide a higher insulation effect in these buildings.

The solution:

insulated steel panels:

It’s important to note that different solutions apply based on what you use a building for.

If you expect humans to use it regularly, for instance a garden room, gym, garden office or warehouse, then the combined need for insulation and a reduction in condensation means insulated roof sheets are the best choice - and they look good aesthetically, too.

Other outbuildings may be better suited to fibre cement roof sheets, which are cheaper and perform well in terms of preventing condensation. But they provide no insulation benefit.

Assuming you require an insulation effect, here are our top tips.

GrafoTherm anti-condensation paint:

A spray or roll applicated anti-condensation coating specifically designed for the underside of steel roof sheets where dripping condensation problems occur. GrafoTherm also has a handy benefit of increasing light reflection and dampens sound making it perfect for working areas that are loud and need good lighting.

Domestic settings:

Our 30mm stock sheet is perfect for most domestic settings, such as garden rooms and garages.

They can be retrofitted and will provide insulation value as well as cutting out condensation.

Thicker panels are available but can incur extra costs, not least because they must be specially made and are more expensive to deliver.

Stock sheets can be picked up and transported yourself. Or, if in stock, they can be delivered in three to five working days.

These panels are also big sellers in the summer when many people are thinking about home improvements.

And with the current energy cost crisis, insulation is more important than ever. Especially in buildings that you intend to spend time in – such as garden offices or garages converted into a gym.

So, we recommend these panels for new-build projects, too.

Industrial settings:

Thicker insulated fibre cement roof sheets are required for industrial buildings, which require a higher insulation value.

For warehouses, for instance, the need to prevent condensation is crucial to protect stock being stored inside the building as well as protecting human health.

Insulation panels in this range will need to be specially made, cut to length for your project. A choice of colours are available.

However, it is important for businesses to plan ahead and to factor in increased delivery charges. The lead time for thicker bespoke insulated panels is normally at least four weeks.

Other options:

Fibre cement can also be a solution for some projects because they have the ability to absorb up to 25% of their dry weight in moisture and dissipate it in more favourable conditions. This has a significant effect in reducing condensation.

Fibre cement is therefore a cost-effective option which is significantly cheaper than insulated steel panels, but only viable if you do not require an insulation value. In addition, anti-condensation steel sheets or Onduline do not condensate and are viable alternatives.

It’s always a good idea to contact us in advance about your project to talk through which are the best materials to use. We’ll be happy to provide advice.