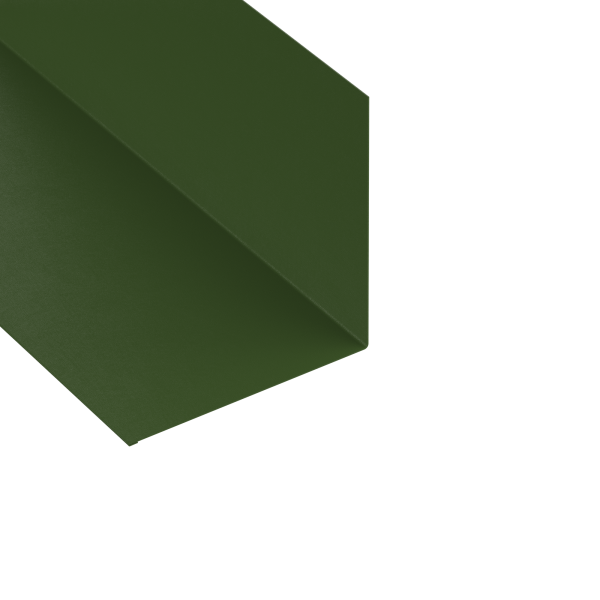

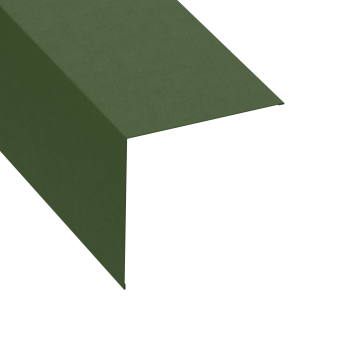

3.0m long Abutment Flashing, 190mm x 190mm x 100°, Plastic Coated

This item is made to order. For competitive prices, fast lead times, further information or to place an order; please contact our friendly sales team of product experts:

Monday - Thursday: 8am - 5:30pm

Friday: 8am - 4pm

Interested in this product?

You can use the form below and email us to enquire about this non-stocked product.

Technical Specifications

- Length - 3.000m

- Dimensions - 200mm x 200mm

- Angle - 100 degrees

- Finish - Leathergrain Plastic Coating

- Material - Galvanised Steel

- Thickness - 0.7mm

- Weight - 6.24kg

- Colour Side - Internal

- Lap - 100mm Minimum

- Edges - Un-welted

Manufactured in 3.0m lengths from a plastic-coated leathergrain material in heavier gauge 0.7mm sheet for strength and rigidity, whilst maintaining some flexibility to aid installation. The flashing legs measure 200mm with the internal angle at 100-degrees.

- Length - 3.0m long

- Dimensions - 200mm x 200mm x 100deg. Internal angle

- Colour - Available in Juniper Green (BS 12B29) & Goosewing Grey (BS 10A05)

- Colour Side – Internally coloured

- Finish – Leathergrain, Plastic Coated

- Edge Detail - No welts (safety edges)

NEED A CUSTOM FLASHING? Made-to-order flashings are available, please contact our Sales Team for more information.

- Lightweight & easy to handle

- Easy to install

- Colour matched to sheets

- Plastic coated for a stronger finish

Where do I use an abutment flashing?

An abutment flashing is used the bridge the void where roof sheets meet a vertical wall, to provide a weathertight seal.

What is the reccomended overlap of adjoining abutment flashings?

The minimum ovelap of adjoining abutment flashings should be 150mm.

How do I install an abutment flashing?

To install an abutment flashing, the vertical leg of the abutment flashing should sit flush with the wall to create a weathertight seal, it then needs be fixed into place using appropriate screws, you then need to fix the lower leg of the abutment flashing to the crown of your roof sheet.

Can I get different sized flashings?

Yes, we can manufacture made to order flashings. If you want to make an enquiry, please contact our sales team

How do I calculate the angle I need?

The angle of abutment you need is calculated by adding the roof pitch degree to 90°. E.G if your roof pitch is 20°, it would be 90° + 20° = 110°

Is there any flexibility in the abutment flashing?

There is a small amount of flexibility in the ridge, so if you are using our 110° stock ridge you will be able to flex it some degrees either way.

Can Southern Sheeting cut flashings?

We are unable to cut our stock flashings, however we can provide made to order flashings to specific lengths.

Can I get different sized flashings?

Yes, we can manufacture made to order flashings. If you want to make an enquiry, please contact our sales team.

-

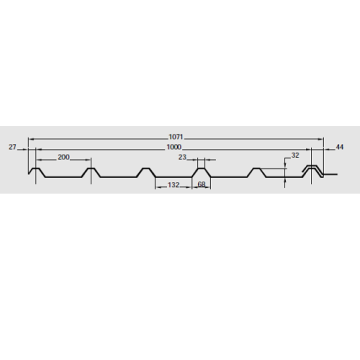

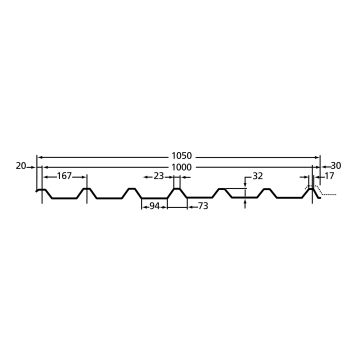

32/1000 Box Profile Steel Sheet, 0.5mm thick, Polyester Coated, Goosewing Grey - Custom Length£12.79 £10.66 Per Metre

32/1000 Box Profile Steel Sheet, 0.5mm thick, Polyester Coated, Goosewing Grey - Custom Length£12.79 £10.66 Per Metre -

32/1000 Box Profile Steel Sheet, 0.7mm thick, Plastic Coated, Juniper Green with Anti-Con£21.74 £18.12 Per Metre

32/1000 Box Profile Steel Sheet, 0.7mm thick, Plastic Coated, Juniper Green with Anti-Con£21.74 £18.12 Per Metre

Find the right materials and support for your project

We can help! View our supportive help guides and videos.

Our supportive guides and help videos will help you achieve the best results. Our knowledgeable team can also offer helpful tips, and support to help you plan and purchase what you need!